3D printer pushes prototyping boundaries

Making the construction of prototypes more efficient, cost-effective, faster and flexible—this will be possible with the world’s largest industrial delta 3D printer. The four-meter-high machine was developed by Professor Yilmaz Uygun’s research group at Jacobs University Bremen. The project exhibits promising potential for industrial application and further research and cooperation opportunities for the university in Bremen-Nord.

In industries such as spare parts management, prototype construction, and mechanical and plant engineering, individualized parts are regularly required, which poses a challenge for these industries; on one hand the parts are complex in structure but are, on the other hand, only needed in small quantities. Conventional manufacturing processes are hardly suitable for the production of such individual parts. It is uneconomical, sometimes even impossible, to produce these necessary parts—depending on their size and complexity.

This is where the project of Professor Yilmaz Uygun and his team at Jacobs University Bremen comes into play. Supported by the Kieserling Foundation, the research team led by Serkan Özkan has developed the world’s largest industrially usable delta 3D printer within a very short time. This additive manufacturing process makes it possible to efficiently produce complex individual parts for prototypes that are still in the test phase. This means that their design can be flexibly and economically adapted to the test results and renewed as required.

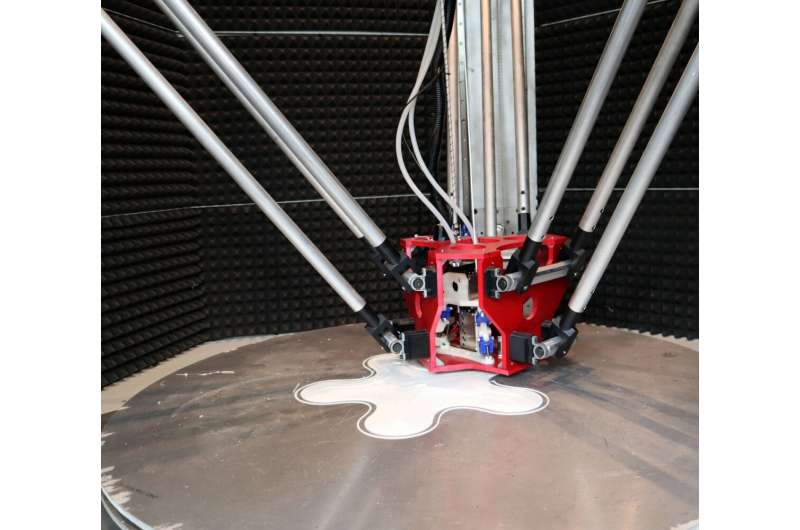

The 3D printer has a height of over four meters and offers a printing area of up to 1.5 meters in radius and a printing height of up to 2.5 meters—making it one of a kind due to its design. The printer head hovers above the printing plate, attached to three arms that form a triangle—a delta. The printer head can be moved in any direction via the arms. The printing area that results from this allows for the printing of exceptionally large parts.

The printed parts are created using the additive manufacturing process are currently used in vertical wind turbines as part of a university project. Further projects for various industries are planned. The printing speed is currently around 5kg per hour—depending on the complexity of the desired printout.

The speed as well as the printing material—currently filament, i.e. strings consisting of conventional plastics such as PLA, PET or ABS—are aspects where Uygun still sees great potential in the future.

Excess material, which is printed as a support structure for curved and fine parts and subsequently disposed of, could be shredded and recycled as pellets: “We are currently developing a pellet extruder to be able to produce pellets and use them as input material instead of filament,” said Uygun. “This radically reduces the carbon footprint. In addition, we can reduce costs, secure the supply chain and ensure independence from specific suppliers and regions,” explained the Professor of Logistics at Jacobs University.

Uygun and his team are also focusing on further developing quality management during the printing process. One measure they are working on deals with a camera-based system that monitors the printing process visually. In the long term, “Honeycomb,” as the 3D printer has been named, should correct itself in the event of deviations in the print. “Our goal is to bring Honeycomb directly into production. We have several ideas to speed up printing without sacrificing quality.” The team is researching the simultaneous use of multiple print heads with nozzle openings of different sizes, which would be used for product geometries of varying complexity and at correspondingly different speeds. “If this is successful, the system could be used directly in production,” said Uygun.

They chose the name Honeycomb because it describes the internal structure of the printed parts. The honeycomb structure renders an outcome with less material and the manufactured piece is light and stable. Another contribution to efficiency and sustainability. “There are already several interested parties for pilot projects,” said Uygun.

New 3D printing process is faster and more precise than conventional methods

Provided by

Jacobs University Bremen gGmbH

Citation:

3D printer pushes prototyping boundaries (2022, August 24)

retrieved 24 August 2022

from https://techxplore.com/news/2022-08-3d-printer-prototyping-boundaries.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.