Additive manufacturing: Simulated from start to finish

Additive manufacturing of tools using a laser powder bed fusion process offers a great number of advantages: It is economical, precise and allows for customized solutions. That said, it can be difficult to determine the optimal process parameters, such as the scan speed or power of the laser.

For the first time, researchers at Fraunhofer are now simulating the process at the microstructure level in order to identify direct correlations between the workpiece properties and the selected process parameters. To do this, they are combining a number of different simulation methods.

Additive manufacturing offers numerous advantages. Most notably, energy and materials can be saved, and complex component geometries and customized products can also be realized. The laser powder bed fusion process, or LPBF for short, is a widely used process for the additive manufacturing of components and tools: This process impresses with its short innovation cycles and high cost-effectiveness.

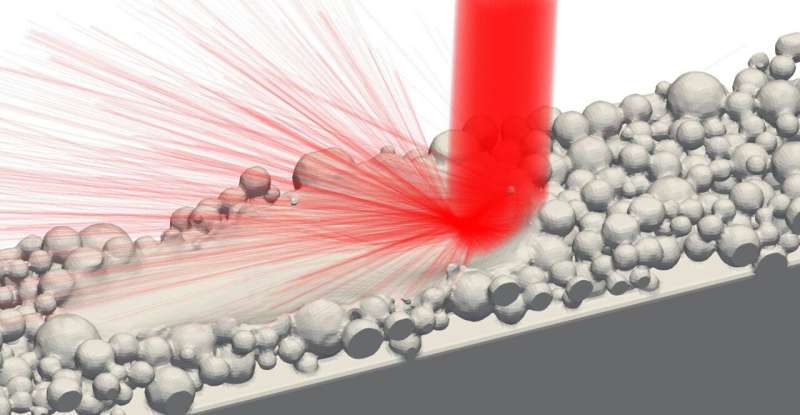

The principle here is that a powder bed up to 50 micrometers thick is heated with pinpoint accuracy by a laser. The powder liquefies, the particles fuse and the melt pool solidifies as soon as the laser moves on. In areas where the laser beam does not come into contact with the powder, no fusion occurs. This process is repeated numerous times, causing the component to grow in height layer by layer.

It is important that the finished component has a density of 100%, no pores, and that each newly applied layer binds firmly to the layer below. This is achieved by adjusting the process parameters, such as the scan speed and power of the laser. The microstructure of metallic grains is particularly important for the mechanical properties of the workpiece. These have certain orientations, sizes and shapes and have a considerable impact on the mechanical properties, such as the material’s elastic modulus or the yield stress—i.e., the load above which the material deforms plastically.

So the question is: How do you control the process in such a way that the resulting microstructure is suited to the component’s future conditions of use? Furthermore, components and workpieces are often made out of different metallic alloys: steels, aluminum alloys, titanium alloys with various compositions and mixing ratios. Each alloy material has different properties and forms different microstructures. Finding the optimal process parameters and materials and matching them to each other has, up to this point, been an experimental and therefore time-consuming endeavor.

Simulating the entire process chain

Researchers at the Fraunhofer Institute for Mechanics of Materials IWM are now taking a different approach. “Because the laser powder bed fusion process is becoming increasingly complex due to new materials and requirements, we have decided to simulate the entire process chain,” explains Dr. Claas Bierwisch, team leader at Fraunhofer IWM. “This enables us not only to minimize trial-and-error cycles, but also to quickly and effectively evaluate variations in the overall process and eliminate undesirable effects during manufacturing.”

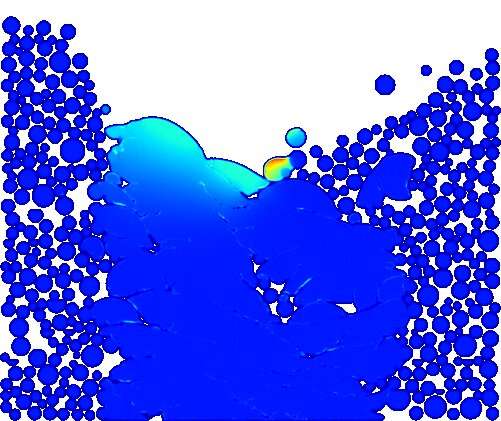

The important thing here is that the researchers have combined different simulation methods. Using the discrete element method, they first simulate how the individual powder particles are spread in the building chamber with the aid of a special tool, namely the doctor blade. Next, the way in which the powder particles melt is simulated using the smoothed particle hydrodynamics method—both the laser interaction and heat conduction are calculated, as well as the surface tension that causes the melt to flow. The calculation also accounts for gravity and the recoil pressure that occurs when the material vaporizes.

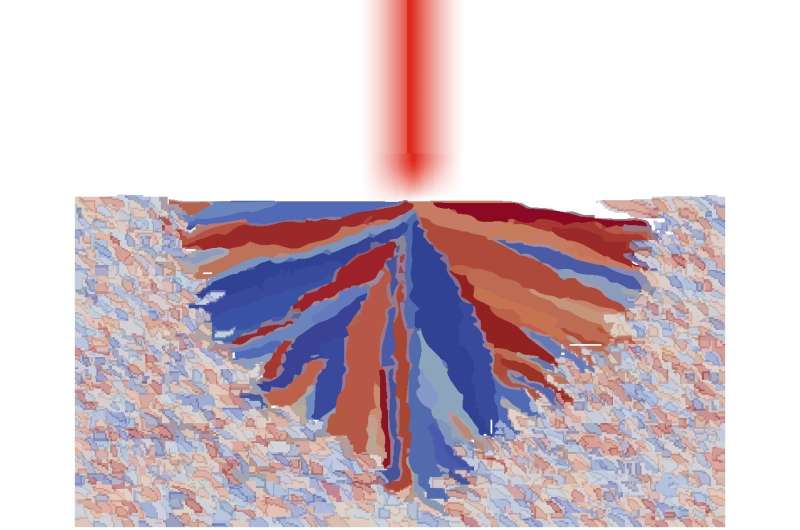

The simulation must also describe the microstructure of the material in order to predict mechanical material properties. “To analyze this microstructure, we have incorporated another simulation method, known as cellular automaton. This describes how the metallic grains grow as a function of the temperature gradient,” explains Bierwisch.

This is because temperatures can reach up to 3,000 degrees Celsius where the laser meets the powder, but only a few millimeters away, the material is cool. Furthermore, the laser moves over the powder bed at a speed of up to several meters per second. As a result, the material heats up extremely quickly but then also cools down again within milliseconds. All of this has an impact on how the microstructure is formed. The final step is the finite element simulation: The research team uses this to perform tensile tests in different directions on a representative volume element of the material in order to find out how the material reacts to these loads.

“In the experiment, we can only study the final result, whereas in the simulation, we can watch what happens in real time. In other words, we create a process-structure-property relationship: For example, if we increase the laser power, the microstructure changes. This, in turn, significantly affects the yield stress of the material. The quality of this is completely different to what is possible in an experiment,” says Bierwisch, enthusiastically. “You can detect interrelationships in an almost investigative way.”

Citation:

Additive manufacturing: Simulated from start to finish (2023, January 3)

retrieved 3 January 2023

from https://techxplore.com/news/2023-01-additive-simulated-finish.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.