How AI breaks in power factor on an industrial workhorse motor

Lift the lid on an electrified home, a factory or a mine, and you’ll find a troop of squirrel cage motors active at all hours. Industrialized nations wouldn’t be nearly as industrial without these.

Rugged and reliable, this type of three-phase induction motor is often the go-to option in industry. These do not produce sparks and fit very well in hazardous environments like oil refineries, mines and grain elevators, and used for grinding, pumping and blowing operations.

At home, the fridge, washing machine, tumble dryer and swimming pool pump are powered by single-phase squirrel cage motors. The motors are especially good for high-speed applications above 3000 rpm. Even better, squirrel cage motors are self-starting and don’t need much maintenance, even if rated at hundreds of horsepower.

However, squirrel cage motors can cause disruptive power bill penalties for large companies. In South Africa, the national broadcaster often runs ads in the evenings encouraging people to switch off their home appliances and pool pumps.

AI to play nice

In short, there is a huge demand for high-performance, value-for-money workhorse motors. But the managers of power grids also demand that these motors cause limited disruption.

Dr. Mbika Muteba from the University of Johannesburg trained an AI to optimize the design of a squirrel cage motor. The study is published in the journal Energies. The AI ensured that the optimized design causes little disruption to the power grid to which it is connected by significantly improving the motor’s power factor.

In this research, Muteba modeled and designed rotors and auxiliary capacitive coils for a 5.5kW (7.37 metric horsepower) squirrel cage motor. Then he built the rotors and tested them in the laboratory. The motors’ real-world performance matched the predicted performance closely.

The first motor tested doesn’t have an auxiliary coil on the stator and isn’t optimized by AI. The second has an auxiliary coil to improve power factor and is also not optimized by AI. The third motor has an auxiliary coil on the stator and is also optimized by the AI algorithm. The genetic algorithm optimized it for the highest performance across various loads on electrical current drawn (torque per ampere). Muteba verified the genetic algorithm’s results with finite element analysis.

The AI-optimized 5.5kW motor had an excellent power factor in the laboratory setup, ranging from 0.93 measured at 0% loading, to 0.99 at 60% loading through to 120% loading. The efficiency at full load of the AI-optimized motor is 85.87%, which is within 1 to 2% of the unoptimized motor. Its efficiency for loads under 30% is also much improved compared to the unoptimized motors.

Most importantly, even with the excellent power factor, the optimized motor gives more torque while drawing less current. The AI optimized design’s torque per ampere was a double-digit improvement on that of the motor without AI optimization.

The optimized motor’s torque per ampere is 22% higher at 20% loading, 16% higher at 60% loading and 13% better at 120% loading, compared to the unoptimized version.

Why squirrel cage motors can make grids unstable

“Squirrel cage motors generally have a poor power factor. Especially if they’re starting or operating under light loads,” says Muteba. “But power companies want all the loads you connect to their grid, whether it is the motor of a pool pump or a machine crushing ore at a mine, to have a good power factor.”

Three-phase power grids provide two kinds of power. The first is active power which turns motors and does the work. Power utilities bill their customers for this in kilowatts or megawatts. Grids also provide reactive power. Squirrel cage motors eat into reactive power on a grid to maintain the magnetic fields on their rotors. Without that field, a squirrel cage motor doesn’t operate. Of all types of electrical motors, squirrel cage motors are the hungriest for reactive power.

Transformers that step down high voltage power to domestic or industrial voltages also eat into the reactive power on a grid. “A load with a poor power factor consumes a lot more reactive power. When hundreds or thousands such loads are connected to a grid, the grid’s owners have to spend to upgrade the grid to provide more reactive power,” he says.

If a grid is overwhelmed by loads with poor power factors, all loads on the grid, even the ones with good power factors, can’t get enough reactive power to operate and the grid can become unstable. This can cause extensive damage in mines, factories, and irrigation systems on farms.

Power utilities penalize users heavily for loads with poor power factors. So a national power grid may have tens or hundreds of thousands of squirrel cage motors connected to it,as dependable workhorses. But the motors’ combined low power factor can make a grid unpredictable and even unstable.

Significant savings

The AI optimization for the rotor and auxiliary capacitive coil made it possible to improve the power factor and performance and still have a reliable, efficient squirrel motor for challenging applications, says Muteba.

The AI-optimized motor has an air gap between rotor and stator, which is larger than in an unoptimized motor. Under high loads, high temperatures and high speeds, the optimized motor should perform better mechanically than the unoptimized motors.

“With these results, we see it is possible to operate squirrel cage induction motors without spending millions on reactive compensators to avoid penalties from utility companies. It is also unnecessary to adopt auxiliary coils in a way that reduces efficiency or torque per ampere,” he adds.

“The AI-optimized rotor and auxiliary capacitive coil has an excellent power factor across the full range of loads, and is still more efficient, at higher performance, as well.”

For a microgrid, or privately owned power grid, building an excellent power factor into each squirrel cage motor makes the grid much easier to manage as well, he says.

AI edge in design

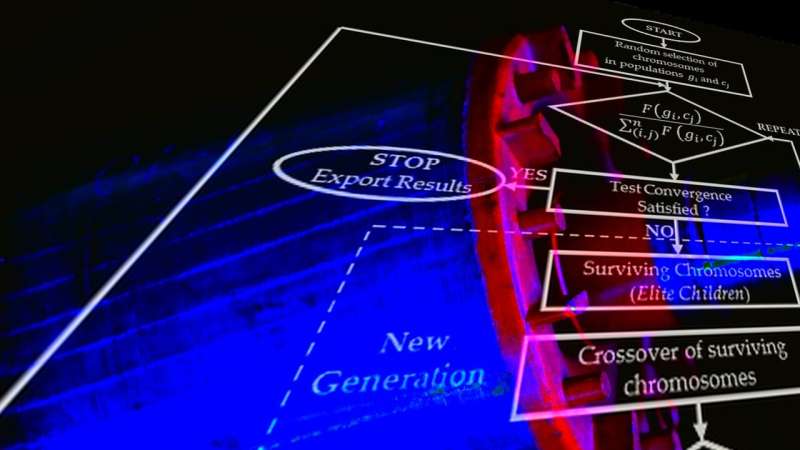

Using AI to optimize the rotor and auxiliary capacitive coil design can save time compared to entrenched design practices, says Muteba. The genetic algorithm took 27 minutes to optimize the rotor and auxiliary capacitive coil design, within eight executions and 60 generations of chromosomes processed.

“Design engineers are faced with the challenge of selecting the optimal value of air gap length and auxiliary capacitive coil. In most cases, they use design software that performs sensitivity and parametric analysis. These processes are usually lengthy, with limited search capabilities,” says Muteba.

“AIs such as optimal search algorithms can find the optimal value of air gap length and auxiliary capacitive coil by searching a large solution space in a matter of minutes. The population-based technique, used in this research, a genetic algorithm, is a good fit to find the required optimal values.”

Mbika Muteba, Optimization of Air Gap Length and Capacitive Auxiliary Winding in Three-Phase Induction Motors Based on a Genetic Algorithm, Energies (2021). DOI: 10.3390/en14154407

Provided by

University of Johannesburg

Citation:

How AI breaks in power factor on an industrial workhorse motor (2021, October 19)

retrieved 19 October 2021

from https://techxplore.com/news/2021-10-ai-power-factor-industrial-workhorse.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.