Perovskite solar cells from the slot die coater represent a step towards industrial production

Metal halide perovskites are considered to be a particularly low-cost and promising class of materials for next-generation solar modules. Perovskite solar cells can be produced with coating processes using liquid inks made from precursor materials and various solvents. After coating, the solvents evaporate and the perovskites crystallize to form a more or less homogeneous layer.

Prof. Dr. Eva Unger’s team at Helmholtz-Zentrum Berlin has extensive expertise in solution-based processing methods and is investigating options for upscaling.

“Perovskite photovoltaics is the best solution-processable PV technology available,” says Eva Unger, “but we are only just beginning to understand how the complex interaction of the solvent components affects the quality of the perovskite layers.”

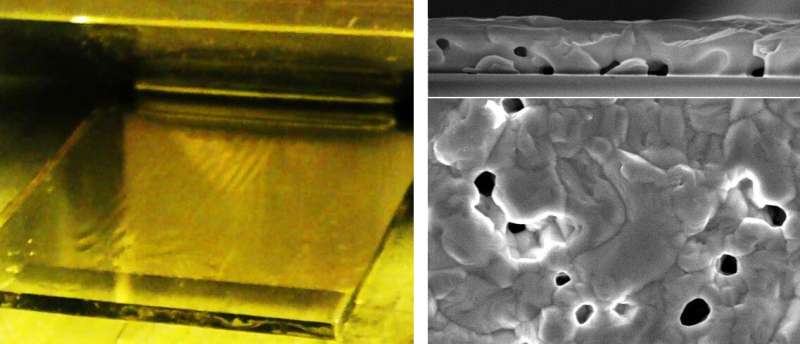

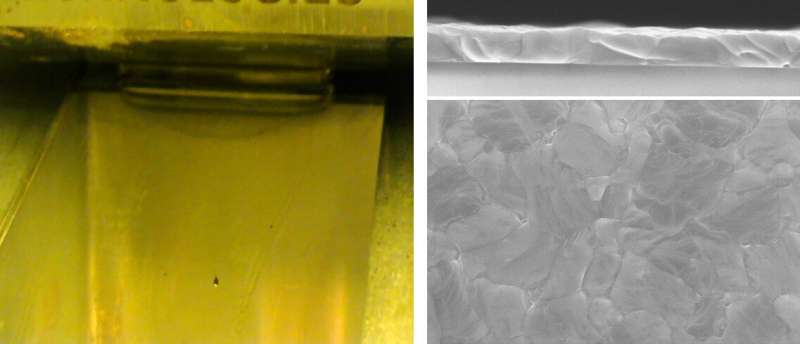

This is because when the halide perovskite layers are coated on large surfaces, unwanted inhomogeneities can occur, for example so-called ribbing structures.

“By varying the viscosity of the ink, such effects can be minimized,” says Jinzhao Li, who is doing his Ph.D. with Unger. At BESSY II, he has investigated how different solvent combinations affect the crystallization of the perovskite films.

The best p-i-n-FAPbI3 perovskite solar cells thus achieve a certified efficiency of 22.3 % on a laboratory scale. Jinzhao Li also produced mini solar modules (active area of 12.6 cm2) with colleagues from the HySPRINT innovation lab and PVcomB, which achieved efficiencies of around 17 %.

Dr. Carolin Ulbrich’s team tested the optimized solar cells at PVcomB’s outdoor test facility for a whole year: In the process, the efficiency remained almost stable in winter and spring, and only dropped in the warmer summer months. “These tests of larger modules under real conditions give us valuable information on degradation mechanisms to then further improve the long-term stability of halide perovskite photovoltaics,” says Eva Unger.

The paper is published in the journal Advanced Energy Materials.

More information:

Jinzhao Li et al, Ink Design Enabling Slot‐Die Coated Perovskite Solar Cells with >22% Power Conversion Efficiency, Micro‐Modules, and 1 Year of Outdoor Performance Evaluation, Advanced Energy Materials (2023). DOI: 10.1002/aenm.202203898

Citation:

Perovskite solar cells from the slot die coater represent a step towards industrial production (2023, March 16)

retrieved 16 March 2023

from https://techxplore.com/news/2023-03-perovskite-solar-cells-slot-die.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.