Second-tier structure matters for regulating liquid spreading dynamics

Conventional understanding holds that the spreading direction of liquids with different properties is dependent on the design of surfaces and cannot be tailored. However, a recent work published in Science demonstrates that it is possible to make liquids with different surface tensions select their spreading directions on the same surface composed of 3D macro ratchets with dual reentrant curvatures.

Nevertheless, the fabrication of such sophisticated structures relies on the combination of 3D printing and polishing treatment to eliminate the inevitable microgrooves-like surface deficiency generated from the layer-by-layer printing process, which increases the manufacturing complexity and is unfavorable for practical applications.

The research, published in the International Journal of Extreme Manufacturing, shows how to simplify the surface topography and fabrication process while simultaneously maintaining the function of liquid directional steering.

This work provides a new idea of turning waste into treasure. Instead of eliminating the rough surface defect of 3D printing by an additional polish treatment, the work makes use of the seeming deficiency to flexibly regulate the spreading phase map of liquids.

“It provides a new design of surface that is easy to fabricate or replicate, without sacrificing the function of liquids directional steering,” said Zuankai Wang, a chair professor in the Department of Mechanic Engineering at The Hong Kong Polytechnic University and the corresponding author of the study. “Essentially, it suggests new possibilities for making use of the often overlooked or useless part of materials to realize desired function,” said Jing Sun (postdoc at City University of Hong Kong), the first author of the paper.

Liquid directional transport is a ubiquitous phenomenon in nature. Lots of biological surfaces, such as the back of desert beetles, the silk of spider and the beak of bird, possess the ability of directionally transport liquid by taking advantage of their special surface morphologies or chemistries. In recent years, many researchers have endeavored to mimic this kind of liquid movement by the control of asymmetric micro/nanostructures, wettability gradient, or external energy input.

Without exception, in all of the previous studies, the liquids always transport along directions that reduce surface energy. A question arises, whether liquids can select their transport direction without changing the surface structure and without energy input? In the Science article, researchers discovered an unexpected liquid transport behavior on the Araucaria leaf, which consists of three-dimensional (3D) ratchets with transverse and longitudinal reentrant curvatures, on which liquids with low surface tensions and high surface tensions spread along opposite pathways.

The sophisticated ratchets with dual-reentrant curvatures can be first fabricated by 3D printing, however, the layer-by-layer printing process would bring in microgroove-like surface defect and an additional polish treatment is needed to smooth the surface to fulfill the designed curvature, which increases the fabrication complexity and is unfavorable for practical application.

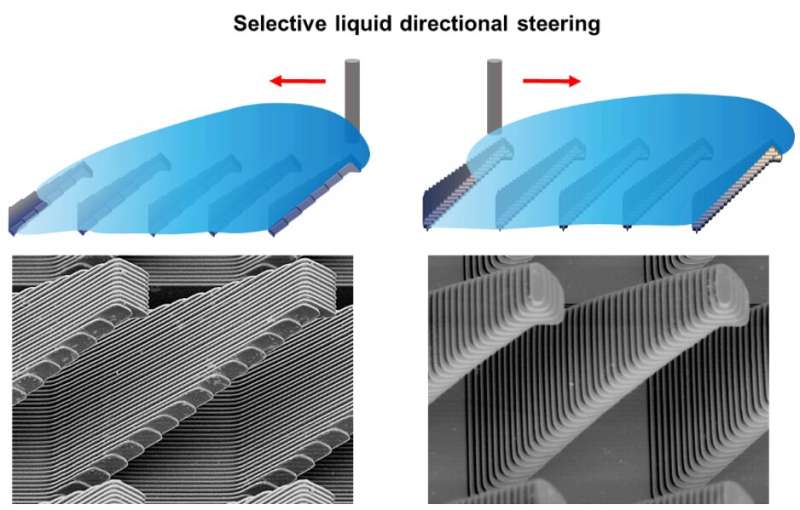

How to make use of the surface defect instead of eliminating it? Sun and colleagues designed a simplified dual-scale ratchet that can be fabricated by one-step 3D printing. The dual-scale ratchet is macroscopically featured as an A-shaped island with a reentrant tip, and microscopically covered with microgrooves. After tests, they found that the simplified dual-scale ratchets can realize liquid directional steering similar to that found on Araucaria leaf.

The research did not end there. “We are curious how and to what extent can the second-tier microgroove structures rectify the spreading dynamics of liquids, so we prepared ratchets with microgrooves arranged along different orientations,” said Sun. Experiments demonstrated that the orientation of microgrooves indeed plays a dominant role in regulating liquids with moderate wettability, and liquids could even spread along opposite directions on ratchets with microgrooves oriented perpendicular and parallel to the ratchet-tilting direction.

“Microgrooves arranged perpendicular to the ratchet-tilting direction serve as delay valve to slow down the spreading of liquids on the side surface of ratchets, whereas microgrooves parallel to the ratchet-tilting direction would promote the spreading of liquids due to capillary wicking, thus the latter is more beneficial for the backward spreading of liquids,” said Wang. They also verified the role of microgrooves through theoretical analysis and simulation.

The team is also exploring the deeper mechanism of the liquid-solid interaction and more functions the materials might make. “What we know is just the tip of the iceberg, more advanced visualization tools may be employed to reveal how the liquid and solid structures interact in the microscale, or we can even introduce other functions by adding different ingredients to the materials,” said Wang.

More information:

Jing Sun et al, Selective liquid directional steering enabled by dual-scale reentrant ratchets, International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/acccbc

Provided by

International Journal of Extreme Manufacturing

Citation:

Second-tier structure matters for regulating liquid spreading dynamics (2023, May 12)

retrieved 12 May 2023

from https://techxplore.com/news/2023-05-second-tier-liquid-dynamics.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.