Strategy for promoting adaptive grasping, dexterous manipulation, and human-robot interaction with tactile sensing

Hands possess an awe-inspiring ability to perceive friction forces with remarkable accuracy, all thanks to the mechanical receptors nestled within skin. This natural gift allows objects to be handled deftly and tools to be wielded effortlessly, infusing daily life with a delightful flexibility. But what if this tactile prowess could be unlocked in robots?

Imagine a world where robots possess the uncanny ability to detect and understand friction and slip, just like we do. This tantalizing concept fuels the pursuit of flexible tactile detection, a cutting-edge field that aims to equip robots with a sense of touch akin to our own. By delicately navigating the intricate landscape of friction, robots could conquer diverse operations with precision and grace.

While strides have been made, the development of flexible 3D force sensors is still wobbling through its research stage. Unlike their rigid beam-based counterparts, these sensors hold incredible promise, capable of conforming to various surfaces and executing tasks requiring finesse. However, researchers are still grappling with the challenges from complex structures, intricate decoupling methods, and inconsistent performance.

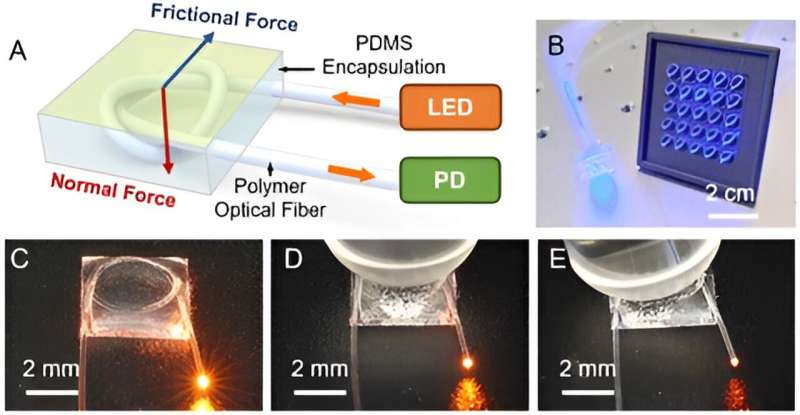

Drawing inspiration from knots, an interesting idea presents itself—polymer optical fiber knots. The knot’s three-dimensional structure breaks the fiber’s original circular symmetry, redistributing the load on the fiber surface. In turn, this empowers individual fiber units to respond uniquely to force stimuli from different directions, promising the creation of intricate 3D force sensing devices.

Polymer optical fibers boast a host of advantages: compactness, robustness, simplified fabrication processes, and cost-effectiveness. This study unravels their responses to directional forces and demonstrates their potential for 3D force measurement.

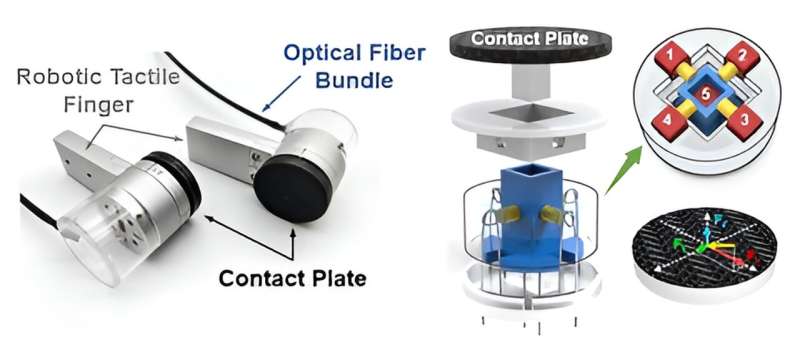

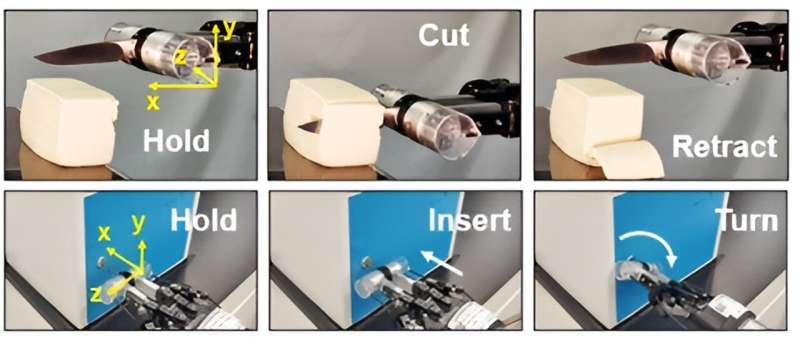

Building upon this knowledge, an array of fiber knots is meticulously designed and brought to life, enabling successful 3D force detection. By integrating these sensors at a robot’s fingertips, tactile information including pressure, friction and slips becomes accessible. The robotic hand can leverage this intelligence to flawlessly execute advanced tasks such as adaptive grasping and tool manipulation.

This work, published in the journal Opto-Electronic Advances, introduces a new strategy in the construction of 3D force sensors through the combination of knots and optical fibers. By analyzing the structure mechanics of the knot, researchers have successfully improved the sensing performance for pressure, friction and slips. This approach simplifies the system complexity and overcomes computational challenges associated with signal decoupling.

The integration of a change point detection algorithm enables real-time data processing and selection, resulting in a tactile feedback system for robotic manipulation. This system measures the normal and shear forces, and detects slips, allowing robots to adaptively grasp objects and manipulate tools. Demonstrations presented in this article include the adaptive grasping of moving objects and the dexterous manipulation of a knife and a key with a two-fingered robotic hand.

The use of polymer optical fiber makes the knot sensor lightweight, flexible, and inexpensive. The non-metallic nature of the sensor makes it immune to electromagnetic interference. The fabrication process is straightforward and does not require sophisticated micro/nano-processing techniques, significantly lowering the barrier for sensor production.

Furthermore, the polymer optical fibers not only serve as sensing elements but also act as signal transmission channels. This feature simplifies the signal acquisition process of the sensor array, which is beneficial to system integration. Additionally, a single polymer optical fiber can be used to create multiple fiber knots, allowing for additional functions through the incorporation of functional materials or strategies such as multi-wavelength signal multiplexing.

More information:

Jing Pan et al, Knot-inspired optical sensors for slip detection and friction measurement in dexterous robotic manipulation, Opto-Electronic Advances (2023). DOI: 10.29026/oea.2023.230076

Provided by

Compuscript Ltd

Citation:

Strategy for promoting adaptive grasping, dexterous manipulation, and human-robot interaction with tactile sensing (2023, November 3)

retrieved 5 November 2023

from https://techxplore.com/news/2023-11-strategy-grasping-dexterous-human-robot-interaction.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.